Blog: Innovations & Insights

January 2026

Why Is Pelletizer Blade Sharpening Essential for Consistent Pellet Quality?

The pellet that fails quality control tells a story nobody wants to hear. It might reveal contamination, temperature problems, or feed rate issues. But more often than anyone admits, it exposes the gradual betrayal of dull blades masquerading as functional cutting tools. Pelletizer blade sharpening isn’t scheduled maintenance that operations perform when convenient—it’s the difference between producing premium pellets and expensive waste. Yet most facilities treat sharpening like an oil change, something to do eventually rather than a critical quality control measure. The evidence hides in plain sight: dimensional variations, increasing fines, customer complaints about flow properties. All symptoms of the same disease—blades that cut but don’t cut well.

The Physics of Sharp

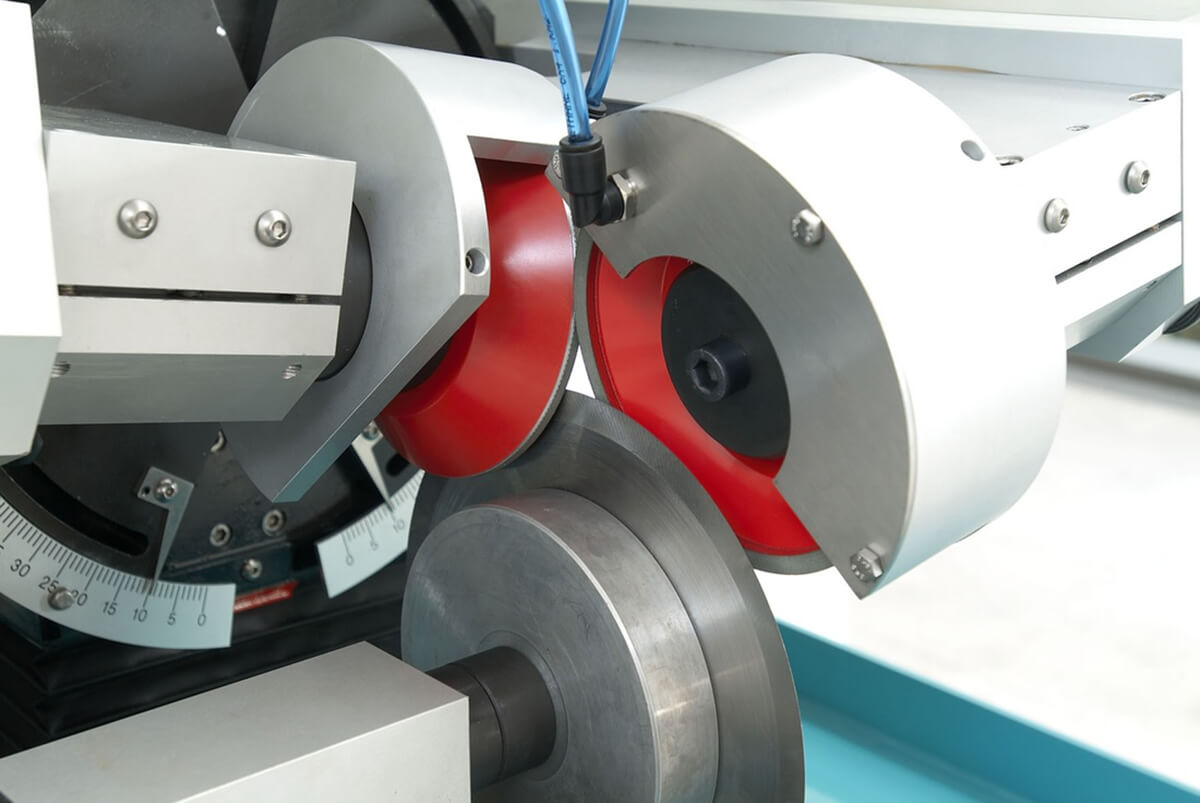

Sharp carbide pelletizer blades don’t just cut cleaner—they fundamentally change how polymer separates at the molecular level. A truly sharp edge creates a shearing action that breaks polymer chains cleanly along a defined plane. The cut surface remains smooth, dimensions stay consistent, and thermal damage stays minimal because the cutting action happens quickly with minimal friction.

Contrast this with what happens as edges dull. Instead of shearing, dull blades tear and deform material. The polymer stretches before separating, creating rough surfaces and inconsistent dimensions. More energy gets converted to heat rather than cutting, raising local temperatures enough to affect polymer properties. What should be a clean mechanical separation becomes a messy combination of tearing, melting, and deformation.

The microscopic reality surprises operators who think their blades are “sharp enough.” Under magnification, an edge that looks acceptable might show micro-chipping, rounding, or buildup that dramatically affects cutting performance. Even 0.0001″ of edge rounding changes cutting dynamics enough to affect pellet quality. Industrial knife sharpening that maintains truly sharp edges requires understanding these microscopic realities.

This becomes critical in underwater pelletizing dies where rapid cooling follows cutting immediately. Dull blades create more heat, affecting how quickly pellets solidify. The surface irregularities from poor cutting trap water, causing drying problems. The dimensional inconsistencies affect how pellets pack and flow. Everything downstream suffers when edges aren’t genuinely sharp.

Quality Degradation Patterns

Pellet quality doesn’t fall off a cliff—it erodes gradually as blades dull, creating a predictable pattern that observant operators can track and prevent through proper pelletizer blade sharpening schedules.

The first sign usually appears in dimensional consistency. What started as ±2% variation might creep to ±3%, then ±5%. Individual pellets might still look acceptable, but statistical analysis reveals increasing spread. Customers with tight specifications notice first, complaining about feed rate variations in their equipment.

Fines generation accelerates as edges degrade. Sharp carbide pelletizer blades create minimal fines—perhaps 0.2-0.5% by weight. As edges dull, fines climb to 1%, then 2%, sometimes higher. These aren’t just lost material; they’re contamination sources that affect entire batches. Fines stick to pellet surfaces, creating feeding problems and appearance issues.

Surface quality deteriorates visibly as sharpening gets delayed. Smooth, glossy pellets develop matte finishes from rough cutting. Under magnification, surface tears and deformation become obvious. These surface defects affect more than appearance—they change flow properties, bulk density, and moisture absorption characteristics.

Length-to-diameter ratios start varying as dull blades struggle to cut cleanly. Underwater pelletizing dies depend on consistent cutting to maintain pellet geometry, but worn edges create irregular forces that affect how material exits the die. Some pellets come out longer, others shorter, destroying the consistency customers expect.

The Hidden Costs

The price of delayed pelletizer blade sharpening extends far beyond the obvious quality issues. Hidden costs accumulate throughout the operation, often unnoticed until someone finally adds them up.

Energy consumption climbs steadily as edges dull. Those carbide pelletizer blades that once cut with minimal force now require significantly more energy to push through polymer. Motor loads increase 20-30% or more. Hydraulic pressures climb. The entire system works harder to achieve inferior results. A facility running 8,000 hours annually might waste $50,000 or more in excess energy costs simply from running dull blades.

Die wear accelerates when blades don’t cut cleanly. The polymer that should exit smoothly instead creates turbulence and pressure variations that stress underwater pelletizing dies. Dies designed to last years might need replacement in months when paired with poorly maintained blades. At $30,000-$50,000 per die, this hidden cost devastates maintenance budgets.

Production capacity drops even when lines keep running. Dull blades force operators to reduce feed rates to maintain quality. What should be a 5,000 lb/hr line might run at 4,000 lb/hr or less. The lost production capacity—often 20% or more—represents pure opportunity cost that proper industrial knife sharpening would prevent.

Customer confidence erodes with each quality complaint. Inconsistent pellets create problems in customer equipment, leading to claims and relationship damage. One major customer lost to quality issues costs more than years of proper pelletizer blade sharpening would have required.

Sharpening Science and Standards

Professional industrial knife sharpening involves far more than running blades across a grinding wheel. The process requires understanding material science, geometry optimization, and the specific demands of pelletizing applications.

Angle precision determines cutting efficiency more than most realize. Carbide pelletizer blades typically require specific angles—often 20-30 degrees—optimized for polymer types and cutting conditions. Deviation of even 2-3 degrees dramatically affects performance. Too acute creates weak edges that chip. Too obtuse requires excessive force. Professional sharpening maintains angles within ±0.5 degrees.

Surface finish affects more than appearance. Proper pelletizer blade sharpening creates mirror finishes measured in micro-inches. This smooth surface reduces friction, prevents material adhesion, and maintains sharpness longer. Rough finishes from improper grinding create microscopic serrations that tear rather than cut, accelerating wear and degrading quality.

The heat generated during sharpening can destroy blade performance before they return to service. Excessive heat creates micro-cracks and residual stresses that cause premature failure. Professional sharpening uses controlled speeds, appropriate coolants, and specific grinding wheels that minimize heat generation. The difference between proper and improper sharpening often shows up as 50% variation in edge life.

Balance matters enormously for rotating blade systems. Uneven sharpening creates imbalance that causes vibration, accelerated wear, and quality problems. Professional services check and correct balance as part of the sharpening process, ensuring smooth operation when blades return to service.

Frequency Optimization

Determining optimal pelletizer blade sharpening frequency requires balancing multiple factors: material type, production volume, quality requirements, and economic considerations. No universal schedule works for everyone, but patterns emerge from successful operations.

Abrasive materials demand more frequent sharpening. Glass-filled polymers might require sharpening every 500-1,000 hours, while unfilled polyolefins might run 2,000-3,000 hours. The key is monitoring performance indicators—fines percentage, dimensional consistency, energy consumption—rather than following arbitrary schedules.

High-value materials justify more frequent sharpening to maintain quality. When processing medical-grade polymers worth $5/lb, the cost of industrial knife sharpening becomes trivial compared to waste prevention. These operations often sharpen at 60-70% of potential blade life to maintain peak quality.

Production schedules influence timing strategy. Some operations maintain multiple sets of carbide pelletizer blades, rotating sharp sets during planned maintenance. Others schedule sharpening during product changeovers, minimizing downtime impact. The best approach depends on specific operational constraints.

Underwater pelletizing dies require special consideration since water cooling affects heat generation and blade wear differently than dry cutting. The rapid temperature cycling and potential for corrosion might necessitate more frequent sharpening even when edges appear acceptable.

The Professional Advantage

Not all sharpening services deliver equal results. The difference between professional pelletizer blade sharpening and “good enough” attempts shows up immediately in performance metrics and long-term costs.

Professional services invest in specialized equipment designed specifically for carbide pelletizer blades. Their grinding machines hold tolerances measured in ten-thousandths, maintaining consistency impossible with general-purpose equipment. They use specific grinding wheels optimized for carbide grades, ensuring proper material removal without subsurface damage.

Documentation distinguishes professionals from amateurs. Quality services provide detailed reports showing measurements before and after sharpening, material removal amounts, and blade condition assessments. This data enables trend analysis and predictive maintenance planning that reduces surprises and optimizes blade life.

Experience with underwater pelletizing dies and various polymer types enables professionals to recommend optimized geometries for specific applications. They understand how different materials affect wear patterns and can adjust sharpening parameters accordingly. This expertise often proves more valuable than the sharpening service itself.

Implementation Excellence

Creating an effective pelletizer blade sharpening program requires systematic approach rather than reactive response to problems.

Start with baseline establishment. Document current blade condition, performance metrics, and quality indicators. Measure actual sharpness using appropriate instruments rather than relying on visual assessment. This baseline enables objective evaluation of improvements.

Develop clear standards for acceptable sharpness. Define specific measurements—edge radius, surface finish, angle tolerance—that constitute “sharp” for your application. Train operators to recognize degradation indicators before they affect quality. Create go/no-go criteria that remove subjectivity from replacement decisions.

Invest in monitoring capabilities. Simple tools like optical comparators or portable microscopes enable in-place edge assessment. Some operations use laser measurement systems for precision evaluation. The ability to quantify sharpness enables data-driven decisions rather than guesswork.

Track total cost implications. Document not just sharpening costs but energy consumption, quality metrics, die wear, and customer satisfaction. This comprehensive view reveals the true value of proper industrial knife sharpening and justifies investment in premium services.

The Competitive Reality

In competitive plastics markets, consistent pellet quality isn’t optional—it’s essential for survival. Customers have choices, and they choose suppliers who deliver consistent, high-quality products reliably. Pelletizer blade sharpening might seem like a minor detail in complex operations, but it directly impacts the quality that determines customer satisfaction.

The investment in proper sharpening—whether equipment, services, or training—returns quickly through improved quality, reduced waste, and customer retention. When carbide pelletizer blades maintain genuine sharpness, everything else in the system works better. Dies last longer, energy costs drop, and quality complaints disappear.

The operations that understand this treat pelletizer blade sharpening as strategic rather than tactical. They invest in professional services, maintain preventive schedules, and monitor performance continuously. This approach separates market leaders from operations perpetually fighting quality problems.

The edge condition of those blades spinning thousands of times per minute determines whether you’re converting polymer into precision products or creating expensive problems. Make sharpening a priority rather than an afterthought, and watch quality concerns transform into competitive advantages.