Blog: Innovations & Insights

June 2025

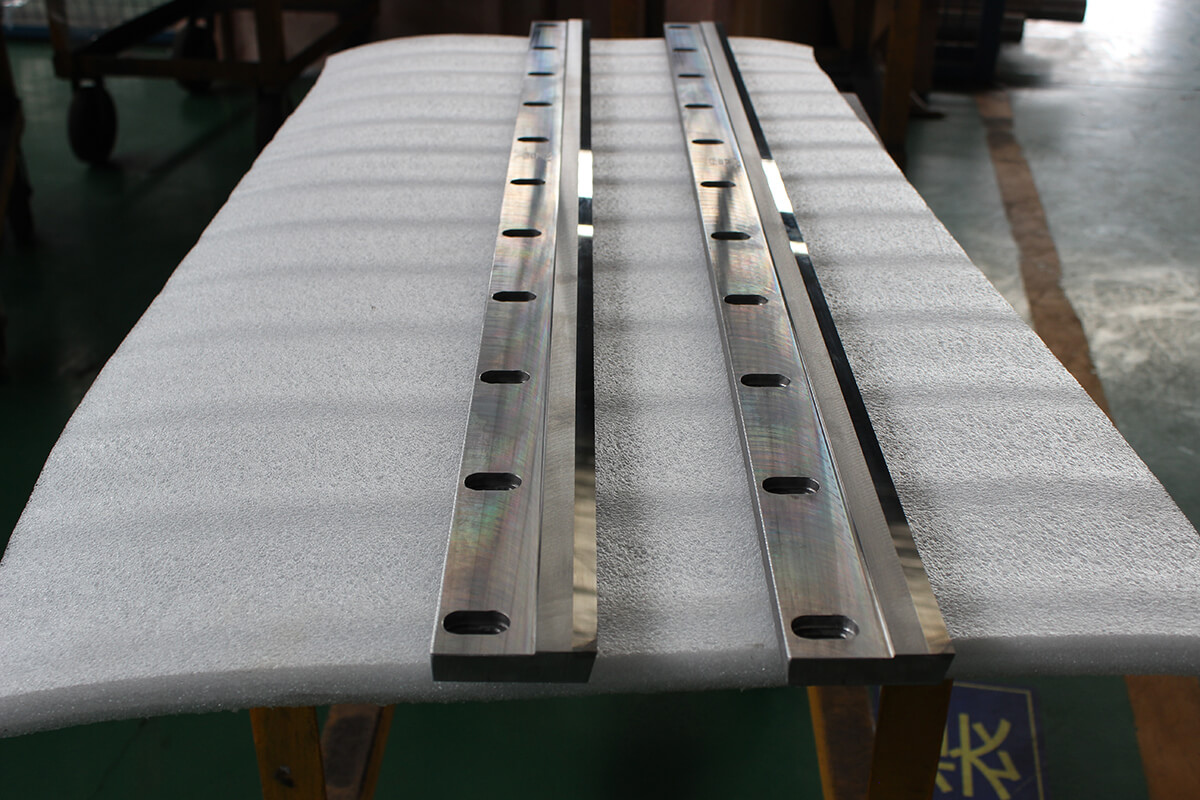

Tungsten Carbide vs. Standard Carbide Knives: Key Differences Explained

Ask most purchasing managers about carbide knives and they’ll tell you carbide is carbide. That assumption has cost plenty of operations serious money and downtime. The reality? Standard carbide and tungsten carbide blades might share a name, but they perform like entirely different materials. One plant manager put it perfectly: “We thought we were being smart buying cheaper carbide knives until we calculated what those ‘savings’ actually cost us in blade changes and poor cuts.” The difference between these materials shows up every day on your production floor.

What Makes Standard Carbide Tick

Standard carbide knives get their properties from combining carbon with various metals—titanium, tantalum, vanadium, and others. These blends create cutting tools that outperform steel significantly while keeping costs reasonable. They’re the middle ground option: better than basic steel but not engineered for the toughest applications.

Most standard carbide formulations target general-purpose cutting where performance matters but isn’t critical. They handle typical plastics processing reasonably well, maintain acceptable sharpness for moderate periods, and cost substantially less than premium alternatives. For many applications, they’re perfectly adequate.

The limitation appears when conditions get demanding. Higher speeds, abrasive materials, or continuous operation expose the compromises built into standard carbide formulations. What seems like acceptable performance initially often deteriorates faster than expected under real production conditions.

Tungsten Carbide: Built for Performance

Tungsten carbide blades take a different approach entirely. The tungsten-carbon combination creates one of the hardest materials available for cutting applications—harder than most tool steels and approaching the hardness of diamond. This isn’t marketing hype; it’s measurable material science that translates into real performance advantages.

The crystalline structure of tungsten carbide maintains its integrity under conditions that would quickly degrade other materials. Heat, pressure, and abrasive contact that destroy standard carbide edges barely affect tungsten carbide performance. This durability advantage becomes particularly valuable in sheeting knives applications where the cutting action never stops.

Processing operations that switched to tungsten carbide often report dramatic improvements in both blade life and cut quality. The material simply holds up better under demanding conditions while maintaining the sharp edge geometry essential for precision cutting.

Hardness Numbers That Matter

The hardness difference between these materials shows up immediately in testing and performance. Standard carbide typically measures 85-90 HRA on the Rockwell scale—good performance that exceeds most steels significantly. Tungsten carbide blades consistently measure 92-95 HRA, representing a substantial increase in hardness.

This hardness advantage translates directly into edge retention. Harder materials resist deformation under cutting loads, maintaining their geometry longer than softer alternatives. For carbide knives cutting abrasive materials or operating at high speeds, this edge retention prevents the gradual performance degradation common with standard carbide.

The hardness advantage becomes even more valuable in applications requiring consistent cut quality throughout extended production runs. While standard carbide gradually loses its edge, tungsten carbide maintains cutting precision far longer.

Wear Resistance in Practice

Laboratory hardness numbers mean nothing if they don’t translate into real-world performance improvements. Wear resistance—how materials hold up under actual cutting conditions—separates tungsten carbide from standard alternatives.

Standard carbide knives show their limitations quickly when processing filled polymers, recycled materials, or contaminated feeds. The abrasive particles common in these applications wear cutting edges rapidly, requiring frequent blade changes and constant attention to cut quality.

Tungsten carbide blades handle these same challenging materials with remarkable resilience. The superior wear resistance means they maintain cutting efficiency even when processing materials that would quickly dull standard carbide. Operations report blade life improvements of 300-500% when switching to tungsten carbide—differences that transform maintenance schedules and operating costs.

Heat Management Advantages

High-speed cutting generates substantial heat, and how cutting materials handle thermal stress directly impacts their performance and longevity. Standard carbide performs adequately at moderate speeds but struggles when cutting conditions generate significant heat buildup.

Tungsten carbide blades manage thermal stress far better through superior heat dissipation and higher temperature tolerance. This thermal advantage proves particularly valuable in high-speed sheeting operations where cutting action is continuous and heat generation constant.

The improved thermal characteristics help maintain cutting edge integrity even under demanding conditions. While standard carbide might soften or lose its edge under high-temperature cutting, tungsten carbide maintains its hardness and geometry.

The Real Economics

Standard carbide knives typically cost 30-50% less than tungsten carbide alternatives—a price difference that initially seems substantial. However, this upfront savings often proves illusory when total operating costs enter the calculation.

The extended service life of tungsten carbide blades reduces both direct replacement costs and indirect expenses associated with blade changes. Production downtime, quality variations during run-in periods, and maintenance labor all decrease when blade changes happen less frequently.

Many operations find that tungsten carbide delivers lower total cost per hour of operation despite higher initial investment. The calculation becomes even more favorable when considering the improved cut quality and consistency that tungsten carbide provides throughout its service life.

Application Matching

The choice between standard and tungsten carbide depends heavily on specific operating conditions:

High-volume operations running continuous schedules typically justify tungsten carbide investment through extended service intervals and improved consistency. The ability to run longer between blade changes directly impacts productivity and profitability.

Abrasive material processing strongly favors tungsten carbide due to its superior wear resistance. Applications involving filled polymers, recycled content, or contaminated materials benefit dramatically from tungsten carbide’s durability.

Quality-critical applications where cut consistency directly impacts product specifications usually require tungsten carbide’s superior edge retention. Standard carbide might start well but degrades too quickly for demanding quality requirements.

Making the Switch

Operations considering the upgrade to tungsten carbide should evaluate several factors:

Document current blade replacement frequency and associated costs to establish baseline performance. Many operations discover they’re changing standard carbide more frequently than realized.

Consider the indirect costs of blade changes beyond the component price. Downtime, quality issues, and maintenance labor often represent the largest expenses associated with cutting tool performance.

Test tungsten carbide on your most challenging applications first. The performance difference typically shows up most dramatically under demanding conditions.

Conclusion

The carbide knife decision comes down to matching material capabilities with operational demands. Standard carbide works adequately for moderate-duty applications where blade changes aren’t disruptive. But demanding operations—high speeds, abrasive materials, continuous production—typically benefit from tungsten carbide’s superior performance despite higher upfront costs. The key is looking beyond initial price to total operating costs and performance requirements. Most operations that make the switch find that the performance difference pays for itself quickly.