Blog: Innovations & Insights

December 2024

The Quick Metals Advantage: Premium Granulator Knives and Sheeting Blades for Plastic Processing

As in any other plastic processing company, the quality of cutting tools can be the greatest determiner of the efficiency. Quick Metals is now recognized as a supplier of the highest quality granulator knives and sheeting blades on the market and leading the way in the industry. These tools are essential in converting the virgin materials into finished products, and thus, choosing the right tools as well as their quality is critical in the processing of plastics. Read on to know why Quick Metals is superior for premium granulator knives and sheeting blades for plastic processing.

The Evolution of Cutting Technology

The journey of granulator blades and sheeting knives has seen remarkable advancement over the years. Modern granulating blades incorporate sophisticated designs and materials that vastly outperform their predecessors. Quick Metals has been at the forefront of this evolution that continuously improve its granulator knives to meet the growing demands of the plastic processing industry. The development of precision-engineered sheeter knives has similarly revolutionized the way manufacturers approach plastic sheeting operations.

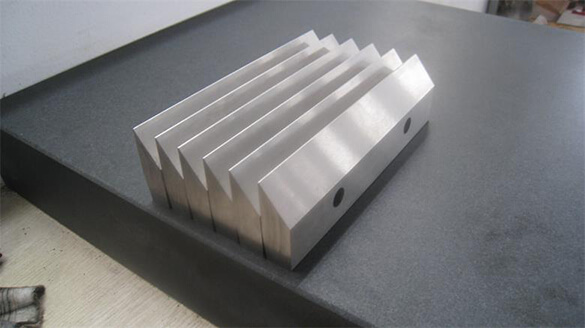

Superior Materials and Construction

Quick Metals’ commitment to excellence begins with material selection. Their granulator knives are crafted from premium-grade steel, specially formulated to maintain sharp edges under intense operating conditions. The manufacturing process of these granulating blades involves precise heat treatment and grinding techniques, ensuring optimal hardness and wear resistance. Similarly, their sheeting knives undergo rigorous quality control measures to maintain consistent performance across all applications.

Design Innovation and Performance

The design of Quick Metals’ granulator blades reflects years of research and development in cutting technology. Each blade features optimized cutting angles and edge geometries that enhance performance while reducing power consumption. Their sheeting knives are engineered with specific applications in mind, whether it’s for thin film production or heavy-gauge sheet processing. The precision-ground edges of these tools ensure clean cuts and minimal waste, contributing to improved operational efficiency.

Applications Across Industries

Granulator knives from Quick Metals find applications in various plastic processing operations. From post-consumer recycling to in-line scrap recovery, these blades handle diverse materials with consistent reliability. The versatility of their granulating blades extends to different types of polymers, including both soft and rigid plastics. In the sheeting sector, their specialized sheeter knives excel in applications ranging from packaging materials to industrial-grade plastic sheets.

Maximizing Operational Efficiency

The implementation of Quick Metals’ cutting solutions leads to significant improvements in operational efficiency. Their granulator knives are designed for quick changeovers, reducing downtime during maintenance. The durability of their granulating blades means longer intervals between replacements, contributing to cost savings. Similarly, their sheeting knives maintain their edge longer than conventional blades, ensuring consistent cut quality throughout their service life.

Maintenance and Care

Proper maintenance of granulator blades and sheeter knives is crucial for optimal performance. Quick Metals provides comprehensive guidelines for maintaining their cutting tools, including recommended sharpening intervals and proper handling procedures. Regular inspection of granulating blades helps identify wear patterns early, allowing for timely maintenance or replacement. Their sheeting knives benefit from similar attention to maintenance, ensuring sustained performance in demanding applications.

Customization and Support

Understanding that every operation has unique requirements, Quick Metals offers customization options for their granulator knives and sheeting blades. Their engineering team works closely with customers to develop specialized solutions for specific applications. This collaborative approach ensures that whether it’s granulating blades for specialized materials or sheeter knives for unique cutting requirements, customers receive tools that perfectly match their needs.

Quality Assurance and Testing

Every batch of granulator knives and sheeting knives undergoes rigorous testing before leaving Quick Metals’ facility. Their quality assurance process includes dimensional verification, hardness testing, and edge quality inspection. This commitment to quality ensures that their granulating blades and sheeter knives consistently meet or exceed industry standards, providing customers with reliable cutting solutions they can count on.

Future Developments

Quick Metals continues to invest in research and development, pushing the boundaries of what’s possible in cutting tool technology. Their ongoing work in advanced materials and innovative designs promises to deliver even more efficient granulator knives and sheeting blades. As the plastic processing industry evolves, Quick Metals remains committed to developing cutting-edge solutions that help manufacturers stay competitive in an increasingly demanding market.

Conclusion

The efficiency of the plastic processing operations mainly depends on the quality and performance of the cutting tools. Quick Metals provides the market with the highest quality and most durable granulator knives and sheeting blades on the market. In this constantly growing industry, their dedication to progress and the highest standards guarantees that manufacturers have the appropriate tools to remain vital in their target niches.